Factory Built Network ®

A patented process for building and deploying complex networks swiftly and predictably

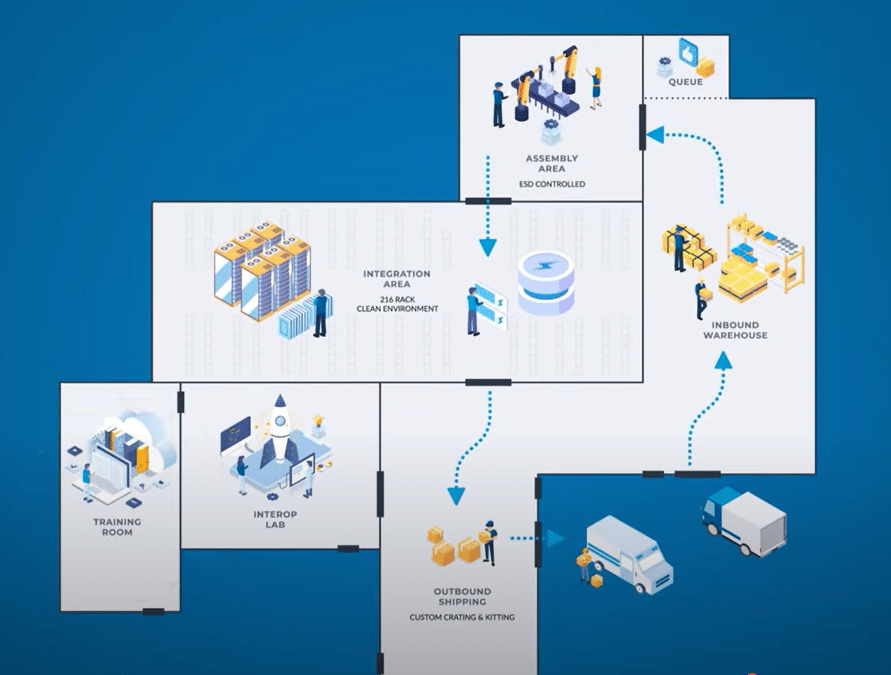

How it works

Leverage our engineering expertise, vendor reach, testing facilities, and multi-vendor automation to deliver higher value networks faster

In combination with our unique multi-vendor technology laboratories and purpose-built network factories, LightRiver specialists build, deploy and support the highest-performing, most reliable transport networks with unprecedented speed and cost-efficiency. After an unparalleled battery of extended testing and burn-in in LightRiver’s facility, networks are deployed rapidly and efficiently in the field, completing new network deployment in record time, while offering an objective prescription for ongoing network health.

Single-source

Single vendor from start to finish accelerates outcomes and improves quality.

In-house

Work performed in-house for better control, improved quality & faster speed.

Global

Equipment is custom-crafted and shipped worldwide.

Reliable

Networks staged, configured, and burned-in at our Factory to prevent issues when deployed

Why Factory Built Network?

Faster deployments, better results

- Vendor agnostic design, integration, and delivery to meet your business needs

- Over 60% less time onsite, including half as many site visits

- 8x more auditing & testing to provide a better performing network

- 94% of quality defects detected during factory testing

- Team empowerment via hands on network training

- Predictable installation schedules

- 50% faster project timelines

- Network monitoring to assure your services are delivered to customers as intended; all contributing to

- 65% reduction in customer staff requirements and associated cost to deploy a new network

Factory Built network Insights

Expertise for every step of your journey